nickel coating thickness measurement|electroless nickel thickness chart : specialty store The deposit properties of an electroless nickel layer and the performance of the plated component depend upon the phosphorous content, the purity, the substrate, the pre treatment, and the thickness of the coating. Electroless nickel solutions operate in a pH 4 - 9 medium at a temperature of between 77 to 198°F (25 - 92°C.) 29 de mai. de 2023 · Aprenda a configurar o DS4Windows, um aplicativo gratuito que permite conectar joysticks DualSense, DualShock 4 e DualShok 3 no Windows 10 e 11. .

{plog:ftitle_list}

Resultado da Click para controlar tu Boleta. Quini 6 en Vivo. Ver el video del sorteo. La fuente más confiable de resultados. . Quini 6 Resultados brinda un servicio gratuito de información y no posee vinculación con organismos oficiales ni con los organizadores responsables de los respectivos sorteos. www.quini-6 .

Measurement of nickel coatings, up to ~ 4 mil (4,000 µ”, 100 µm), are possible using the Phase Sensitive Eddy Current test method. Unfortunately, PSEC is not appropriate .

AN017 Automated coating thickness measurement in production facilities 0.73 MB AN030 Saving costs by using inline measurement for electroplating reel-to-reel applications 0.89 MB AN091 Different ways to achieve valid .Electronic coating thickness instruments can be used to measure coating thickness on metallic substrates. Commonly used techniques are electromagnetic induction and eddy currents. . The Hall Effect measurement .The deposit properties of an electroless nickel layer and the performance of the plated component depend upon the phosphorous content, the purity, the substrate, the pre treatment, and the thickness of the coating. Electroless nickel solutions operate in a pH 4 - 9 medium at a temperature of between 77 to 198°F (25 - 92°C.)The deposit properties of an electroless nickel layer and the performance of the plated component depend upon the phosphorous content, the purity, the substrate, the pre treatment, and the thickness of the coating. Electroless nickel solutions operate in a pH 4 - 9 medium at a temperature of between 77 to 198°F (25 - 92°C.)

However, if a customer were to indicate on a print, “Nickel Plate per QQ-N-290 0.0001”-0.0003”,” this is understood as a range plating thickness requirement because the customer has otherwise specified the thickness desired without indicating the grade.

Measurement of nickel thickness up to ~ 2 mil (2,000 µ”, 50 µm) are possible using the coulometric method. Summary: XRF is often the go-to for measuring nickel and electroless nickel coating. However, XRF does have upper thickness limitations, with nickel coatings becoming challenging to measure starting around 1.2 mil (1,200 µ”, 30 µm).Nickel electroplating is a process of depositing nickel onto a metal part. Parts to be plated must be clean and free of dirt, corrosion, and defects before plating can begin. [3] To clean and protect the part during the plating process, a combination of heat treating, cleaning, masking, pickling, and etching may be used. [1] Once the piece has been prepared it is immersed into an .

soft actuators testing

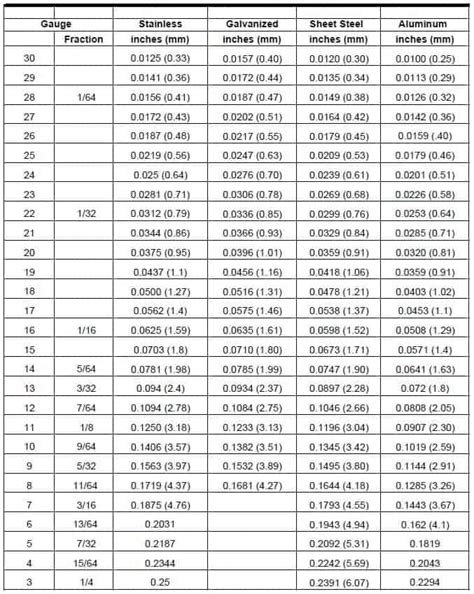

nickel thickness in mm

Electrical wiring: zinc and nickel coatings are replacing older cadmium coatings How XRF measures coatings The Vanta handheld XRF analyzer can measure coating thickness from 0.00 to approximately 60.00 microns, depending on the material. X-rays are emitted from the analyzer, and they strike the sample, causing it to fluoresce. This allows the measurement of more complicated applications, such as multi-layer coating systems and alloy coatings. Since microspot XRF allows non-destructive measurement of composition and thickness, it is an appropriate testing method. It needs only a few seconds to provide real-time, repeatable, and accurate analysis without using purge . Section snippets Experimental theory. As shown in Fig. 1, the coordinate of brush electro-plating nickel coating specimen was defined. In the coordinate, a 1 direction was parallel to the stress loading direction, a 2 direction was vertical to the stress loading direction, a 3 direction was vertical to the coating specimen surface and the propagating depth of Rayleigh .stationary XRF methods, making measuring coating thickness on large and heavy parts unpractical without cutting samples. Now, this limitation can be overcome . curately determine the thickness of electroless nickel over Kovar (18.6 µm vs. 20 µm) as shown in figure B. Also, the results were obtained without previously .

thickness of a nickel/phosphorus coating using X-ray fluorescence without knowing the phosphorus content. The phosphorus content in the nickel changes the coating density and attenuates the other fluoresced components used in the measurement process. For surface stress measurement of brush electro-plating nickel coating specimen, the Rayleigh wave signals of coating specimen with different coating thickness corresponding to different tensile stresses was collected, and the relationship between the difference in time of flight and tensile stress was analyzed based on the property of coating .

A surface ultrasonic wave approach was presented for measuring surface stress of brush electro-plating nickel coating specimen, and the influence of coating thickness on surface stress measurement was discussed. In this research, two Rayleigh wave transducers with 5MHz frequency were employed to col .Coatings for Corrosion Protection: Metallic. S.R. Taylor, in Encyclopedia of Materials: Science and Technology, 2001 2.6 Nickel Coatings. Nickel coatings are commonly applied to steel, zinc, and other metals to provide protection against corrosion, erosion, and abrasion. However, most nickel is consumed in decorative finishes as an interlayer for chromium coatings, while only a .

So I am in need of a good gauge for reading the thickness of electroless nickel on 6061T aluminum, and also to read hard chrome on 17-4 stainless steel. I am looking for a non-destructive method to measure the . A key function to achieving this is accurate plating thickness measurement. The collected data helps determine if the job is running as it should, or if adjustments need to be made to achieve the stated thickness .

Electroless nickel thickness and composition: N/A . CMI155/157: Advanced coating thickness measurement on metal substrates . Rapid and reliable inspection of paint, lacquer, and protective coatings on ferrous and non-ferrous substrates. CMI233: High performance, affordable and rugged design for reliable measurements .nickel coating by thickness up to 2500 µm . The distribution of m agnetization of the coating and base with different value of the prim ary m agnetizing field was researched. The m odule of this magnetization was com puted in the coating along its all thickness and in the base on the depth 500 µm. In fig. 2 the distribution of theGrade C – 0.0015-inch minimum deposit thickness. Electroless Nickel Plating to ASTM B733-04 (and newer) Note: ASTM B733-04 is markedly updated from ASTM B733-90 in that the coating Type specifies the phosphorous content of the coating. ASTM B733-90 does not make this distinction. Type I: No requirement of phosphorous

Now you can measure Nickel coating using Fischer coating thickness measurement gauge.Using a handheld coating thickness tester like the PHASCOPE® PMP10 makes. For testing high alloy, 12-16 percent nickel with large thickness variation, see Table 2. Hull Cell Testing: Maintaining zinc nickel alloy uniformity is critical to providing consistent corrosion protection. Calculation of Electroless Nickel coating thickness, using XRF, while complicated, can be simplified to a core principle, measuring the amount of mass of material within in a known measurement surface area. The measurement surface area is defined by either the collimator size or polycapillary optic spot size. An XRF instrument observes and .B 499 Test Method for Measurement of Coating Thickness by the Magnetic Method: Nonmagnetic Coatings on Mag-netic Basis Metals2 B 507 Practice for Design ofArticles to Be Electroplated on . the specified electroplated nickel thickness or class shall be specified. 5.1.12 Where required, microhardness ranges shall be speci-

In order to control the coating thickness, a professional plating thickness gauge is needed. . I. Various ways to measure the coating thickness; II. LS225 plating thickness gauge measures the coating thickness; . Typical ones are copper and nickel plating on steel. Since the cathodic plating only has a certain thickness, it has a protective . Thickness measurement. We use a thickness gauge to measure the thickness of the nickel coating. This can help to ensure that the coating is applied to the correct thickness for the specific application. Hardness testing. It will need a Rockwell hardness tester to obtain the hardness of the nickel coating.Coating thickness measurement is the determination of the layer depth of a coating or film on a particular substrate. Coating thickness can be measured when the film is wet or dry. However, non-destructive coating thickness measurement .

soft agar colony formation assay golden test for malignant transformation

nickel size in mm

soft agar deep tests for what type of media

nickel size chart

web22 de jul. de 2019 · The casino also accepts PayPal. Withdrawals are not done immediately and may take anything between 1-5 days to do the same. The maximum amount to withdraw every month is C$50,000 . To cater to the global audience, Eurogrand deals in a number of currencies, including the US dollar, GBP, Euro, CAD, CHF, and DKK.

nickel coating thickness measurement|electroless nickel thickness chart